Advantages

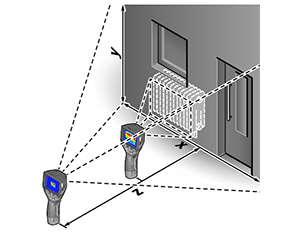

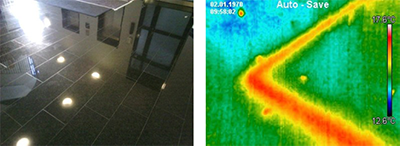

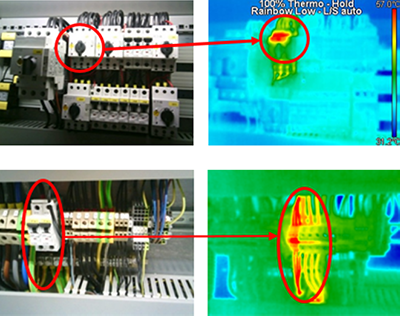

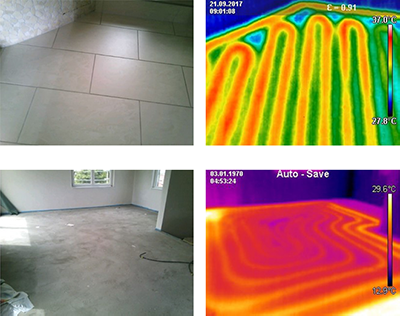

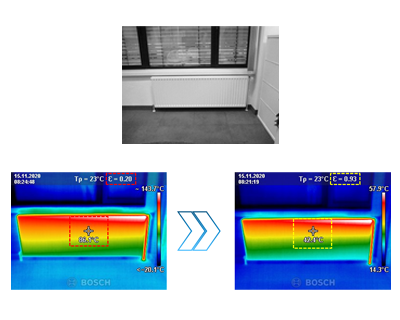

- Contact-free, therefore measuring is possible with objects that ...

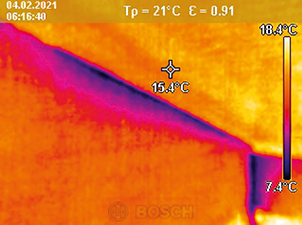

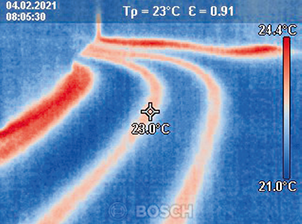

- ... are resting and moving

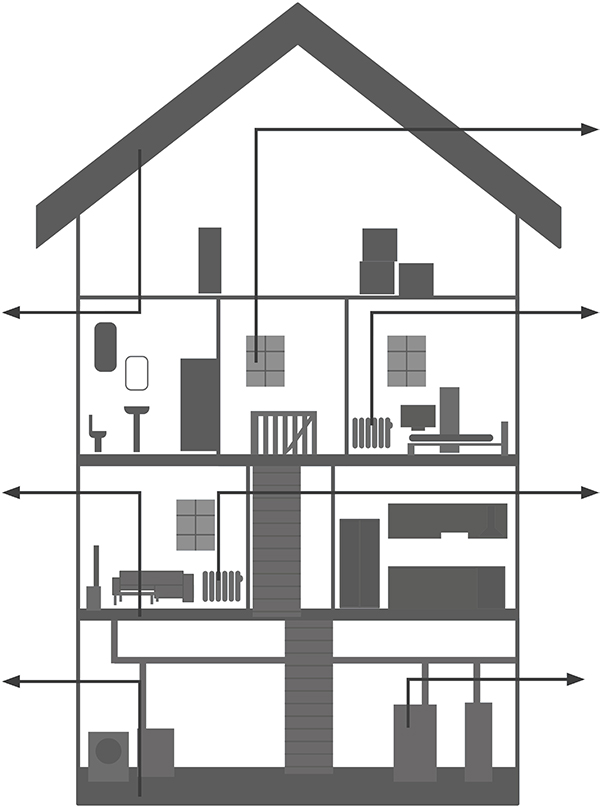

- ... are heavily accessible

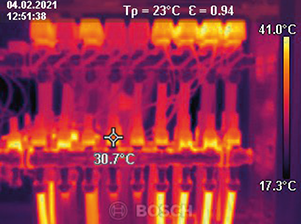

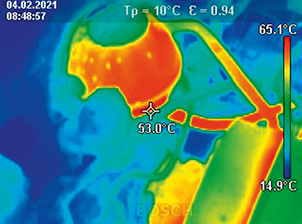

- ... are very hot and

- ... are current-carrying

- Non-reactive and destruction-free measuring

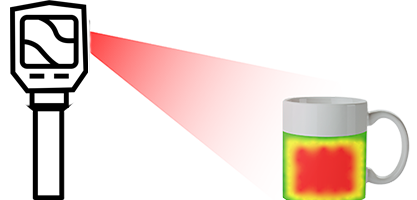

- Very short measuring time

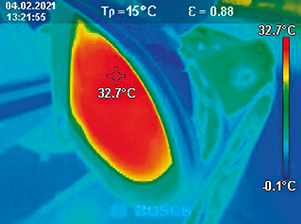

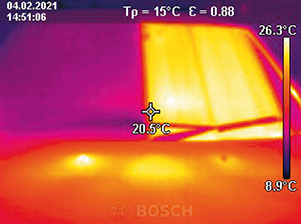

- Area-measured temperature information