a

# B O S C H C A R B I D E

# B O S C H C A R B I D E

Bosch is a leader in Carbide Technology - find out more in this page about:

- What is Carbide?

- What is the particular Bosch Carbide expertise?

Bosch uses carbide components in accessories for many years and even produces its own carbide technology since the 80's.

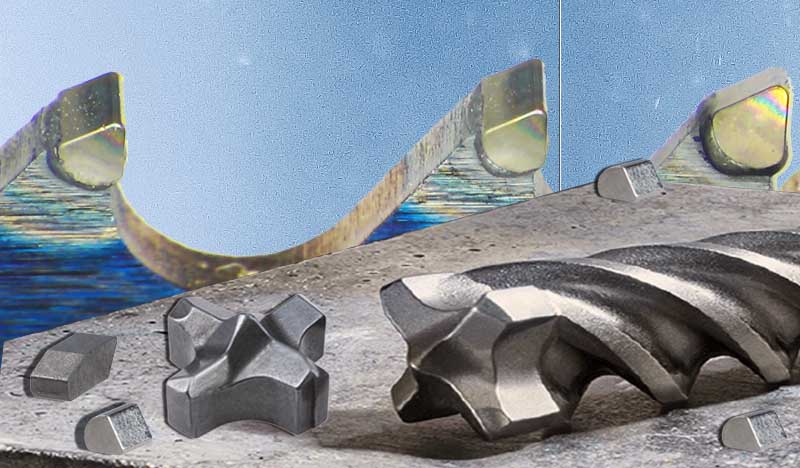

Carbide is one of the hardest and most wear resistant metal. It withstands physical stress, impact, deformation, high temperatures, corrosion and high pressure and is used for working with the toughest materials,

Carbide can be made in various shapes according to the accessory to which it will be bonded after the manufacturing process.

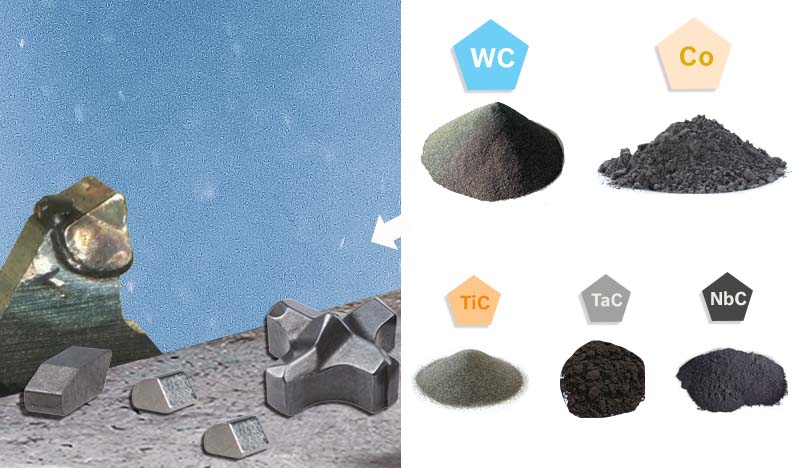

Carbide consists mainly of:

and small portions of different carbide: Titanium carbide (TiC), Tantalum carbide (TaC), or Nobium Carbide (NbC).

Yes according to :

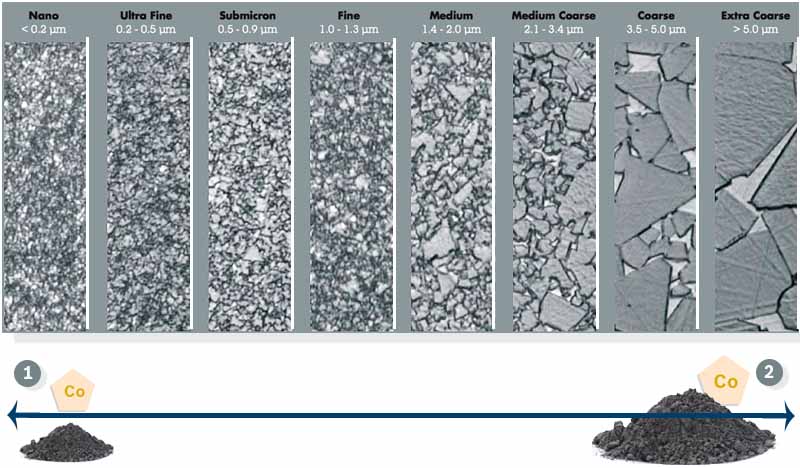

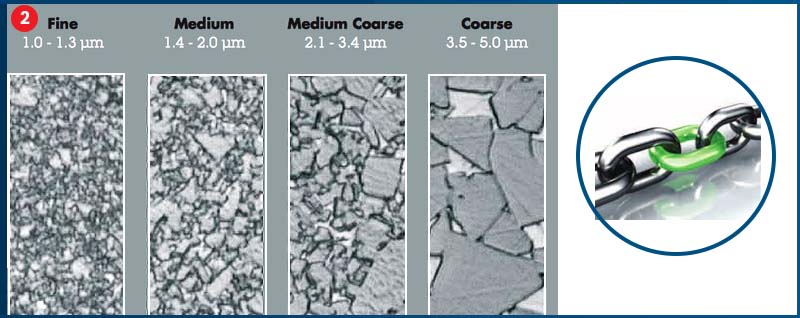

carbide grades differ from a "Nano" microstructure to an "Extra Coarse" microstructure.

+ What is the Bosch advantage?

The invidual grades offer a variation of advantages based on material properties and application requirement.

Bosch is able to produce various carbide grades according to the accessories and the application materials' composition.

First, Tungsten Carbide is produced (1), then Cobalt and other metal (Tic, Tac, NbC) are added and mixed (2). The mixture is milled and dried to produce a material powder (3).

This powder or granulation is put into a mould and pressed (4), then compacted to get the first pre-profiled carbide parts (5).

The pre-profiled carbide parts are placed and baked in a sintering furnace (6) heated at a temperature up to 1600°C and a pressure up to 2000 bars.

The parts are then shaped to accurate geometric shapes in a grinding machine (7). After a final quality control (8) they are ready to be joined to accessories by brazing or welding according to the Bosch carbide technology required (9).

Summary of the key processes

The right carbide technology is required to join the different carbide parts to accessories. The joining method can either be welding or brazing.

What are the carbide technologies used to join carbide parts to accessories?

Used for drill bits. A full carbide head is welded by induction onto the drill bits. It is a unique Bosch welding technology.

+ Carbide Tipped

Used for drill bits. A full carbide head is welded by induction onto the drill bits. It is a unique Bosch welding technology.

+ Carbide Tipped

For jig and recip saw blades, single preformed carbide tips are individually welded by resistance onto stamped and grinded blade body.

For circular saw blades, single preformed carbide tips are individually brazed onto laser cut blade body.

+ Carbide Strip

For jig and recip saw blades, single preformed carbide tips are individually welded by resistance onto stamped and grinded blade body.

For circular saw blades, single preformed carbide tips are individually brazed onto laser cut blade body.

+ Carbide Strip

A carbide strip with many very small tips are welded by laser onto the blade. Excellent for fine cutting and stainless steel. Used for recip saw, jigsaw or Starlock blade.

+ Carbide Grit

A carbide strip with many very small tips are welded by laser onto the blade. Excellent for fine cutting and stainless steel. Used for recip saw, jigsaw or Starlock blade.

+ Carbide Grit

Thousands of small carbide grits (similar to grains of sand) are brazed onto the blade edge. Good for cutting abrasive materials such as tile or cast iron. Used for recip saw, jigsaw or Starlock blade.

Thousands of small carbide grits (similar to grains of sand) are brazed onto the blade edge. Good for cutting abrasive materials such as tile or cast iron. Used for recip saw, jigsaw or Starlock blade.

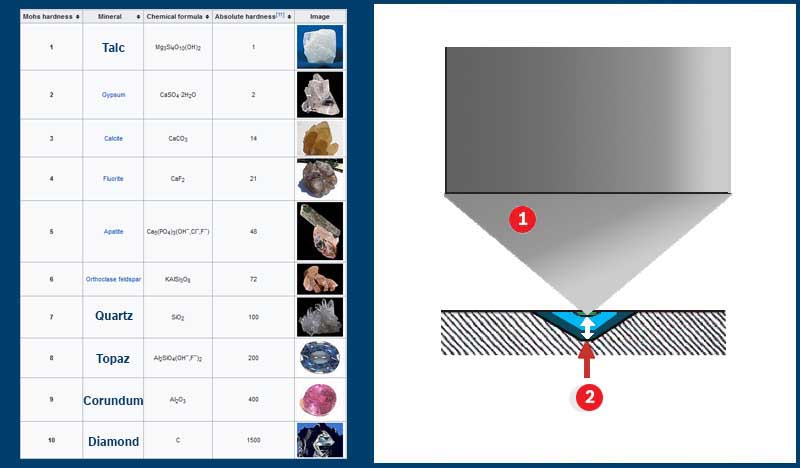

Hardness is the relative ability of one material to wear, abrade, deform or indent another material.

Toughness is the ability of a material to absorb energy and deform without fracturing. This may be easily understood by thinking of a marshmallow being slightly pressed between 2 fingers. It is compressed and extends within its elastic limits. Even metals as Tungsten Carbide extend to a certain degree. The ratio varies with the amount of Cobalt.

The hardness level rises by decreasing the Cobalt content and the particle size of the Tungsten carbide (1).

The toughness level rises by increasing the Cobalt content and the particle size of the Tungsten carbide (2).

+ How to get both - hardness and toughness?

In a system, where two parameters (hardness, toughness) have to be maximized, it is important to find the right balance between each of them.

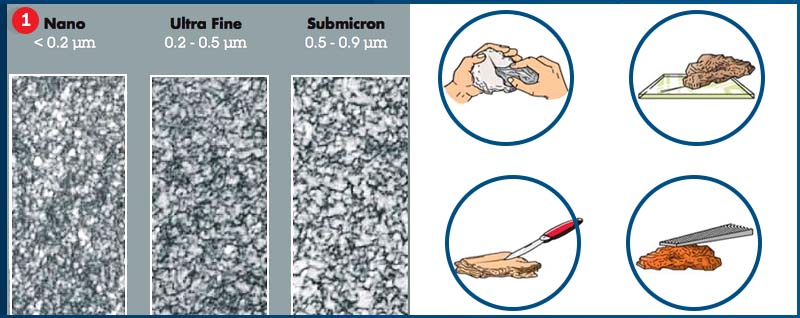

Hardness: with a Cobalt binder in the range of 3-12% by weight and Tungstene grain sizes below 1μm, the Nano, Ultrafine, and Submicron grades have the highest hardness and compressive strengths combined with exceptionally high wear resistance and high reliability against breakage.

Toughness: with a Cobalt binder in the range of 10-20% by weight and Tungstene grain sizes between 1 and 5 μm the other grades have high strength and toughness, combined with good wear resistance.

Test: Hardness of a carbide or a mineral can be measured with the Rockwell "A" or Vickers or Mohs' scale. The test is based on the ability of one mineral to scratch another mineral. Diamonds which are at the top of the scales are the only ones to be able to scratch carbide. The graphic below on the right shows a pointed diamond indenter (1) being forced into a carbide block. The depth of the indent left (2) determines the hardness. On the left the Mohs' scale.

For decades carbide technology has been a focus at Bosch resulting in various product advantages. Select each argument below to find out more.

+ Bosch is the only AC manufacturer producing in-house carbide powders, and powder blends (Cobalt, Tungsten, Titanium, others). Unlike other companies who buy a predefined carbide mixture, Bosch begins the carbide manufacturing process with the raw materials that are mixed and milled in the Bosch competence centers.